2015 System Improvement Projects

1. Storage Tank Mixing Systems

The presence of disinfection by-products (DBPs) in the water supply has been a concern for BCWA during the past few years. DBPs are formed from the interaction of chlorine with naturally occurring organic compounds – such as decaying plants and leaves – which are present in all surface reservoirs. The length of time chlorine is in contact with these naturally occurring organic compounds is also a factor. BCWA receives all of its water supply from the Scituate Reservoir, so the water travels a great distance before it gets to out consumers, and is reacting with the chlorine along the way.

DBPs can be greatly reduced by adding mixing and aeration systems in storage tanks. The two-million gallon Bay View storage tank located in Bristol was the first tank to have this equipment installed. This project has been completed and is operational.

BCWA is presently installing mixing and aeration equipment in the Fountain Avenue storage tank located in Barrington. This project will include new piping that will improve circulation in the tank by having the water enter the tank near the top, and exit at the bottom. Additional pipes will also be added that will spray water into the tank.

BCWA is presently installing mixing and aeration equipment in the Fountain Avenue storage tank located in Barrington. This project will include new piping that will improve circulation in the tank by having the water enter the tank near the top, and exit at the bottom. Additional pipes will also be added that will spray water into the tank.

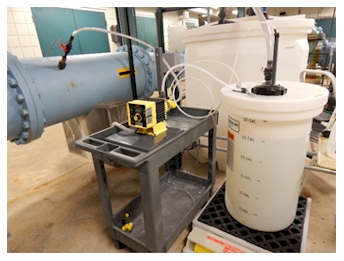

BCWA has also completed the installation of a new automatic chlorine monitoring and injection system at the main connection to the East Bay Pipeline, which is the source of the water supply from Providence and the Scituate Reservoir. This equipment and technology will assist in optimizing the use of chlorine to control disinfection byproducts while maintaining proper levels of chlorine for disinfection purposes.

2. System Control and Data Acquisition (SCADA) Upgrade

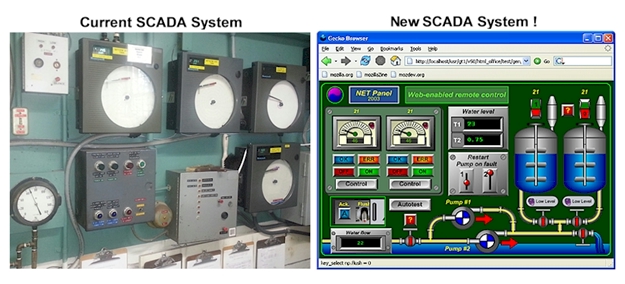

The Bristol County Water Authority is currently in the process of upgrading its System Control and Data Acquisition (SCADA) instrumentation system. A well designed SCADA system provides a water utility with the ability to efficiently monitor and control system operations such as pumping, treatment, and pressure levels. The collection of “real-time” and trending data allows us to discover and correct problems in the distribution system before they become major problems.

A basic SCADA system was originally installed when the cross bay pipeline was constructed in the late 1990s and that instrumentation technology has become outdated. The existing technology did provide us with information that was used to evaluate operations, but it was not always available in as timely a manner or as accurately as we desired.

This SCADA system upgrade will incorporate new radio communication which will instantaneously link all of the BCWA pump stations, storage tanks, control valves together. The operational information from those facilities will integrated into a software package which will allow us to review the operational status of those facilities at any time of the day from any location. The system alarm features will also provide prompt notification of pump failure, pressure loss, and any security issues that may occur, reducing our response time and subsequent impacts to our customers.

When fully operational, this new SCADA technology will enable us to view and analyze system information that was not readily available in the past, giving us the ability to maximize operational efficiencies, prioritize system improvements, reduce expenses, and provide the highest quality water to our customers.

3. Leak Detection Program

The BCWA has undertaken a comprehensive leak detection program to identify and eliminate water lost through underground pipe leaks. Water mains and service lines can fail as they age and the leakage is often not seen above ground. A bad leak can lose thousands of gallons of water a day so it is crucial to find and repair those leaks as quickly as possible.

The BCWA purchased a set of data logging leak correlators to provide employees with the survey tools necessary to find leaks on our pipes. The data loggers are placed on valves and hydrants and left out overnight. They are programed to wake up in the early morning hours when water flow is minimal and “listen” for leaks. What they actually hear and record are the vibrations on pipes caused by leaking water. By comparing the time it takes for the sound of a vibration to travel between data loggers our staff can pinpoint a leak location.

The BCWA purchased a set of data logging leak correlators to provide employees with the survey tools necessary to find leaks on our pipes. The data loggers are placed on valves and hydrants and left out overnight. They are programed to wake up in the early morning hours when water flow is minimal and “listen” for leaks. What they actually hear and record are the vibrations on pipes caused by leaking water. By comparing the time it takes for the sound of a vibration to travel between data loggers our staff can pinpoint a leak location.

This data is downloaded from each logger and analyzed using an accompanying software package. Once verified, BCWA personnel can expedite the pipe repair and stop the water loss. This new technology will be used together with a traditional ground microphone survey to aggressively eliminate water lost through leakage. Each gallon saved by identifying and fixing a leak results in savings for all of our customers.